Mzere Wopangira Margarine wa Puff Pastry

Mzere Wopangira Margarine wa Puff Pastry

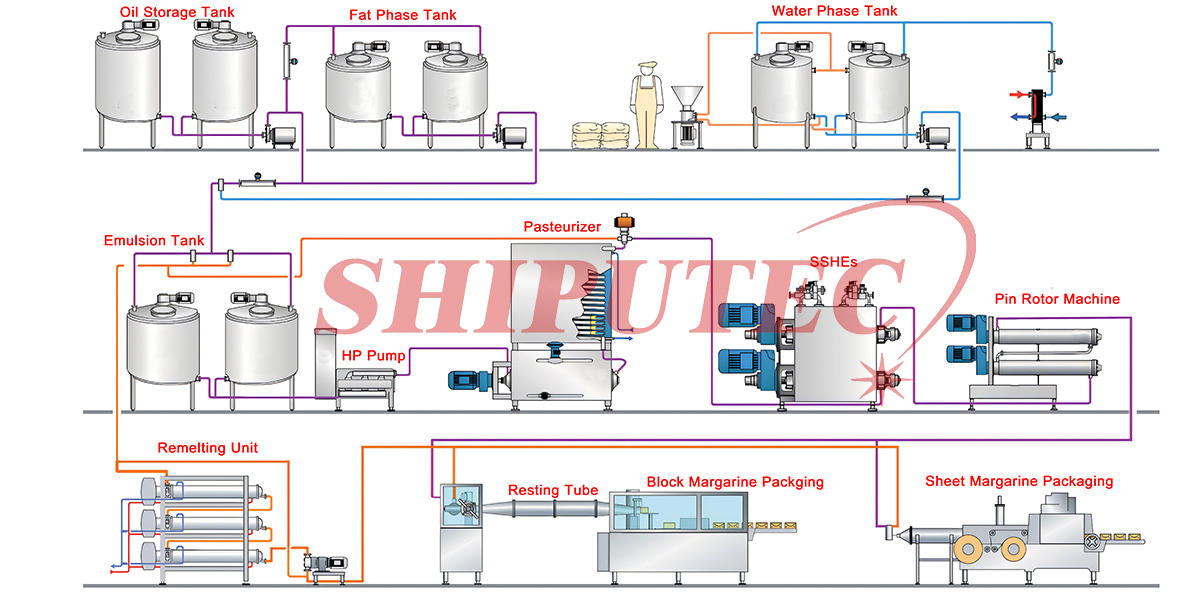

Kanema Wopanga:https://www.youtube.com/watch?v=3cSJknMaYd8

Margarine ndi chinthu cholowa m'malo mwa batala chopangidwa kuchokera ku mafuta a masamba, mafuta a nyama kapena mafuta ena. Njira yopangira ndi kukonza zida zake zakula kwambiri patatha zaka zambiri. Izi ndi njira yofotokozera mwatsatanetsatane komanso kuyambitsa zida zofunika:

I. Njira Yopangira Margarine

1. Kukonzekera Zinthu Zopangira

• Zipangizo zazikulu zopangira:

o Mafuta (pafupifupi 80%): monga mafuta a kanjedza, mafuta a soya, mafuta a rapeseed, mafuta a kokonati, ndi zina zotero, zomwe ziyenera kutsukidwa (kuchotsa chingamu, kuchotsa asidi, kuchotsa utoto, kuchotsa fungo loipa).

Gawo la madzi (pafupifupi 15-20%): mkaka wosaphikidwa mafuta, madzi, mchere, zinthu zosakaniza (monga lecithin, mono-glyceride), zotetezera (monga potassium sorbate), mavitamini (monga vitamini A, D), zokometsera, ndi zina zotero.

o Zowonjezera: mtundu (β-carotene), chowongolera acidity (lactic acid), ndi zina zotero.

2. Kusakaniza ndi Kusakaniza

• Kusakaniza gawo la mafuta ndi gawo la madzi:

Gawo la mafuta (mafuta + zowonjezera zosungunuka ndi mafuta) limatenthedwa kufika pa 50-60℃ ndikusungunuka.

Gawo la madzi (madzi + zowonjezera zosungunuka m'madzi) limatenthedwa ndi kutenthedwa (kusungunuka, 72℃ / masekondi 15).

Magawo awiriwa amasakanizidwa molingana, ndipo ma emulsifier (monga mono-glyceride, soy lecithin) amawonjezedwa, ndipo emulsion yofanana (yamadzi-mu-mafuta kapena yamafuta-mu-madzi) imapangidwa kudzera mu kusakaniza kwachangu (2000-3000 rpm).

3. Kuziziritsa mwachangu ndi kupangitsa kuti zinthu ziume (Gawo Lofunika)

• Kuziziritsa mwachangu: Emulsion imaziziritsidwa mofulumira kufika pa 10-20℃ kudzera mu chosinthira kutentha cha pamwamba (SSHE), zomwe zimapangitsa kuti mafutawo apangidwe pang'ono kuti apange mawonekedwe a kristalo a β' (chinsinsi cha kapangidwe kake kakang'ono).

• Kuumba: Mafuta olimba pang'ono amadulidwa mwa makina kudzera mu kneader (Pin Worker) pa liwiro la 2000-3000 rpm kuti aswe makhiristo akuluakulu ndikupanga kapangidwe kabwino ka mafuta, kupewa kuoneka ngati grit.

4. Kukhwima ndi Kuyika

• Kukhwima: Imasiyidwa kuti iime pa 20-25℃ kwa maola 24-48 kuti ikhazikitse kapangidwe ka kristalo.

• Kupaka: Imadzazidwa ngati mabuloko, makapu, kapena ngati spray, ndipo imasungidwa mufiriji (margarine wofewa amatha kusungidwa kutentha kwa chipinda mwachindunji).

II. Zipangizo Zopangira Zinthu Zapakati

1. Zipangizo zochizira chisanayambike

• Zipangizo zoyeretsera mafuta: kuchotsa gum centrifuge, nsanja yochotsera asidi, thanki yochotsera mtundu, nsanja yochotsera fungo.

• Zipangizo zopangira gawo la madzi: makina opaka pasteurization, homogenizer yothamanga kwambiri (yogwiritsidwa ntchito popangira mkaka kapena gawo la madzi).

2. Zipangizo Zopangira Emulsification

• Thanki ya emulsion: thanki yachitsulo chosapanga dzimbiri yokhala ndi ntchito zosakaniza ndi zotenthetsera (monga chosakaniza chozungulira kapena chosakaniza chamtundu wa turbine).

• Homogenizer yothamanga kwambiri: onjezerani kuyeretsa madontho a emulsion (kupanikizika 10-20 MPa).

3. Zipangizo Zoziziritsira Mwachangu

• Chosinthira Kutentha Pamwamba Chodulidwa (SSHE):

o Zimaziziritsa mofulumira mpaka zitazizira pang'ono, ndi chotsukira chozungulira kuti zisawole.

Mitundu yodziwika bwino: Gerstenberg & Agger (Denmark), Alfa Laval (Sweden), SPX flow (USA), Shiputec (China)

• Wogwira Ntchito pa Pin:

o Menya mafuta kudzera m'mapini angapo kuti muwongolere kukula kwa makristalo.

4. Zipangizo Zolongedza

• Makina odzaza okha: a mabuloko (25g-500g) kapena opakidwa mgolo (1kg-20kg).

• Mzere wopaka wosabala: woyenera zinthu zomwe zimatha kusungidwa kwa nthawi yayitali (monga margarine wamadzimadzi wothiridwa ndi UHT).

III. Mitundu ya Njira

1. Margarine Wofewa: Mafuta ambiri amadzimadzi mu mafuta (monga mafuta a mpendadzuwa), palibe chifukwa choziziritsira mwachangu, amapangidwa molingana ndi momwe amafunira komanso kupakidwa.

2. Margarine Wopanda Mafuta: Kuchuluka kwa mafuta 40-60%, kumafuna kuwonjezera zinthu zokhuthala (monga gelatin, starch yosinthidwa).

3. Margarine Yochokera ku Zomera: Fomula ya mafuta a zomera zonse, yopanda mafuta ochulukirapo (sinthani malo osungunuka pogwiritsa ntchito kusinthana kwa ester kapena ukadaulo wogawa magawo).

IV. Mfundo Zofunika Zokhudza Kuwongolera Ubwino •

Mawonekedwe a kristalo: Mawonekedwe a kristalo a β' (oposa mawonekedwe a kristalo a β) amafunika kuwongolera kuchuluka kwa kuzimitsa ndi mphamvu yosakaniza.

• Chitetezo cha tizilombo toyambitsa matenda: Gawo la madzi liyenera kutsukidwa mosamala, ndipo pH iyenera kusinthidwa pansi pa 4.5 kuti iteteze mabakiteriya.

• Kukhazikika kwa okosijeni: Onjezani ma antioxidants (monga TBHQ, vitamini E) kuti mupewe kuipitsidwa ndi ayoni yachitsulo.

Kudzera mu kuphatikiza kwa njira ndi zida zomwe zili pamwambapa, kirimu wamakono wopangira amatha kutsanzira kukoma kwa batala pamene akukwaniritsa zofunikira paumoyo monga cholesterol yochepa ndi mafuta ochepa okhuta. Fomula yeniyeni ndi njira ziyenera kusinthidwa malinga ndi malo omwe chinthucho chilili (monga kuphika kapena kugwiritsa ntchito pamalo odyera).

Kukhazikitsa Malo