Chidule

Ma margarine a makeke ayenera kukhala apulasitiki komanso okhazikika. Njira zopangira ma margarine a makeke zimatha kukonzedwa mosavuta ndi tubularchiller (tubular scraped surface heat exchanger). Pakukonza mafuta mozama, kuziziritsa kumakhudza kwambiri momwe ma margarine a makeke amakhalira. Ma margarine osiyanasiyana amafunika njira zosiyanasiyana komanso momwe amakhalira okhazikika.

Ma margarine a makeke ayenera kukhala apulasitiki komanso okhazikika. Njira zopangira ma margarine a makeke zimatha kukonzedwa mosavuta ndi tubularchiller (tubular scraped surface heat exchanger). Pakukonza mafuta mozama, kuziziritsa kumakhudza kwambiri momwe ma margarine a makeke amakhalira. Ma margarine osiyanasiyana amafunika njira zosiyanasiyana komanso momwe amakhalira okhazikika.

Mawu ofunikira: margarine wokazinga; ng'oma yozizira; choziziritsira cha tubular, chosinthira kutentha pamwamba, kupanga margarine.

Kuyambitsa kwaukadaulo kwa chiller cha tubular

Ngakhale kuti zinthu zopangidwa ndi margarine wosweka zakhala zikupangidwa kwa zaka zambiri, anthu akhala akuyesera kupeza njira yabwino kwambiri yogwiritsira ntchito zinthu zosiyanasiyana, makamaka pogwiritsa ntchito njira yopangira zinthu zosiyanasiyana. Asanapange chosinthira kutentha cha scraper, kapena makina oyeretsera chubu, zinthu zonse zopangidwa ndi margarine zinkapangidwa pogwiritsa ntchito makina oyeretsera ndi okanda ng'oma. Chifukwa cha makina oyeretsera chubu ali ndi ubwino wambiri poyerekeza ndi makina ena oyeretsera, kotero tsopano opanga margarine akugwiritsa ntchito kupanga margarine wosweka, pepala ili pa makina oyeretsera chubu kuti apange njira yoyeretsera chubu kuti achite zina.

Makhalidwe akuluakulu a margarine wosweka ndi kusungunuka kwake komanso kukhazikika kwake. Margarine ikapindidwa ndikuzunguliridwa mobwerezabwereza, zigawo ziyenera kukhala zosasweka mu mtanda, kotero kusungunuka ndikofunikira; Kukhazikika nakonso n'kofunika. Ngati margarine si yolimba mokwanira kuti ikhale yofewa kapena mafuta olowa, ndipo ikalowa mu mtanda, gawo la mafuta pakati pa zigawo za mtanda lidzachepa kwambiri.

Kapangidwe ka makina ozungulira ozimitsira ng'oma ndi kosavuta, kungosintha magawo ochepa pakupanga kungapangitse kuti margarine ikhale yolimba. Margarine wophwanyika wopangidwa ndi makina ozimitsira ng'oma ali ndi pulasitiki wabwino, ndi wosavuta kulowa mumafuta, ndipo ndi wokhazikika kwambiri pa kutentha kwakukulu. Makina ozimitsira chubu kuposa makina ozimitsira ng'oma apita patsogolo kwambiri, zomwe zimawonekera kwambiri mu:

(1) Mu zinthu zotsukira chitoliro chotsekedwa, kutseka bwino, mikhalidwe yaukhondo idzasinthanso kwambiri;

(2) Kugwira ntchito mopitirira muyeso, komwe ndikofunikira kwambiri popanga margarine wokazinga;

(3) Kusinthasintha kwabwino, kumatha kusintha liwiro, kupanikizika, mphamvu yozizira ndi zinthu zina zogwirira ntchito.

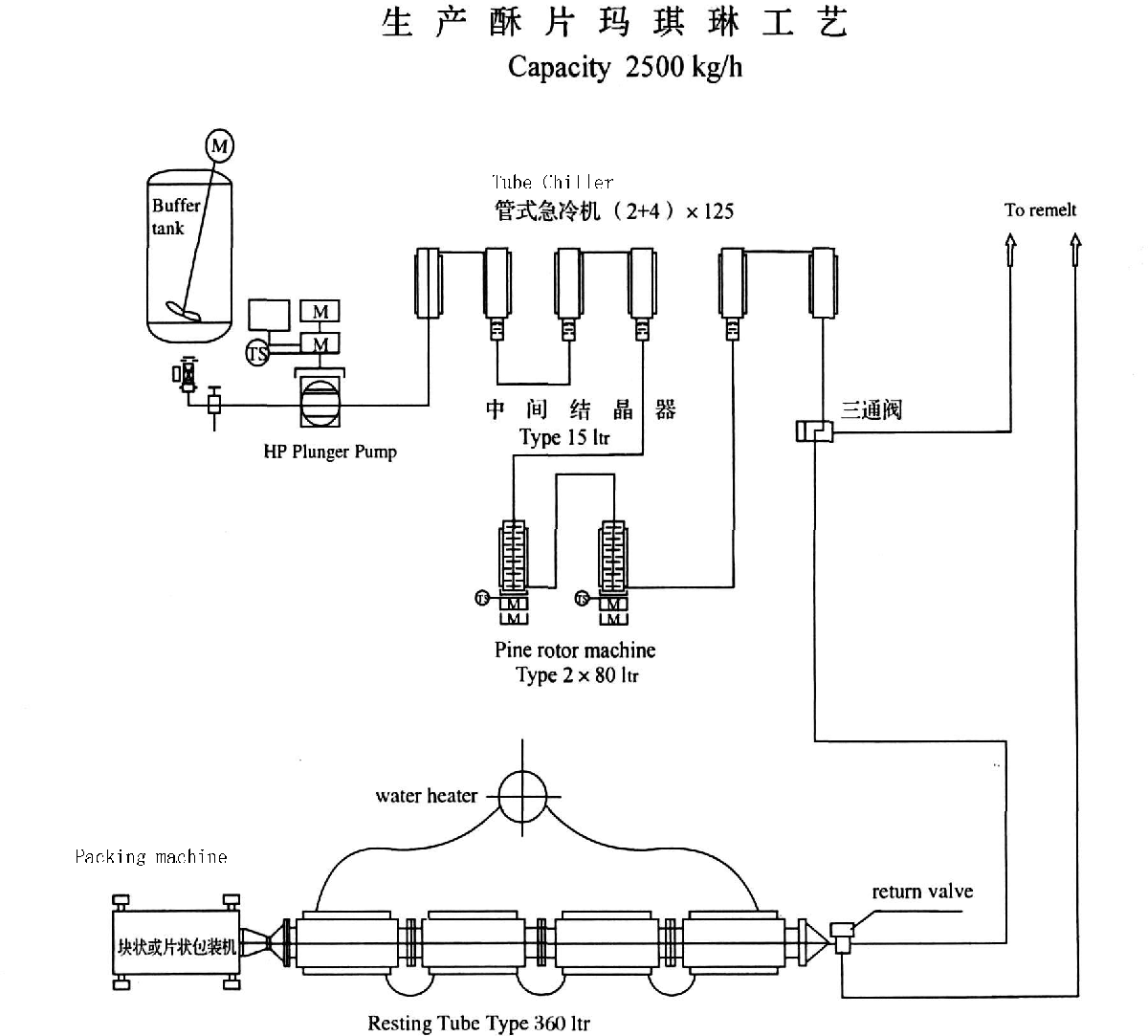

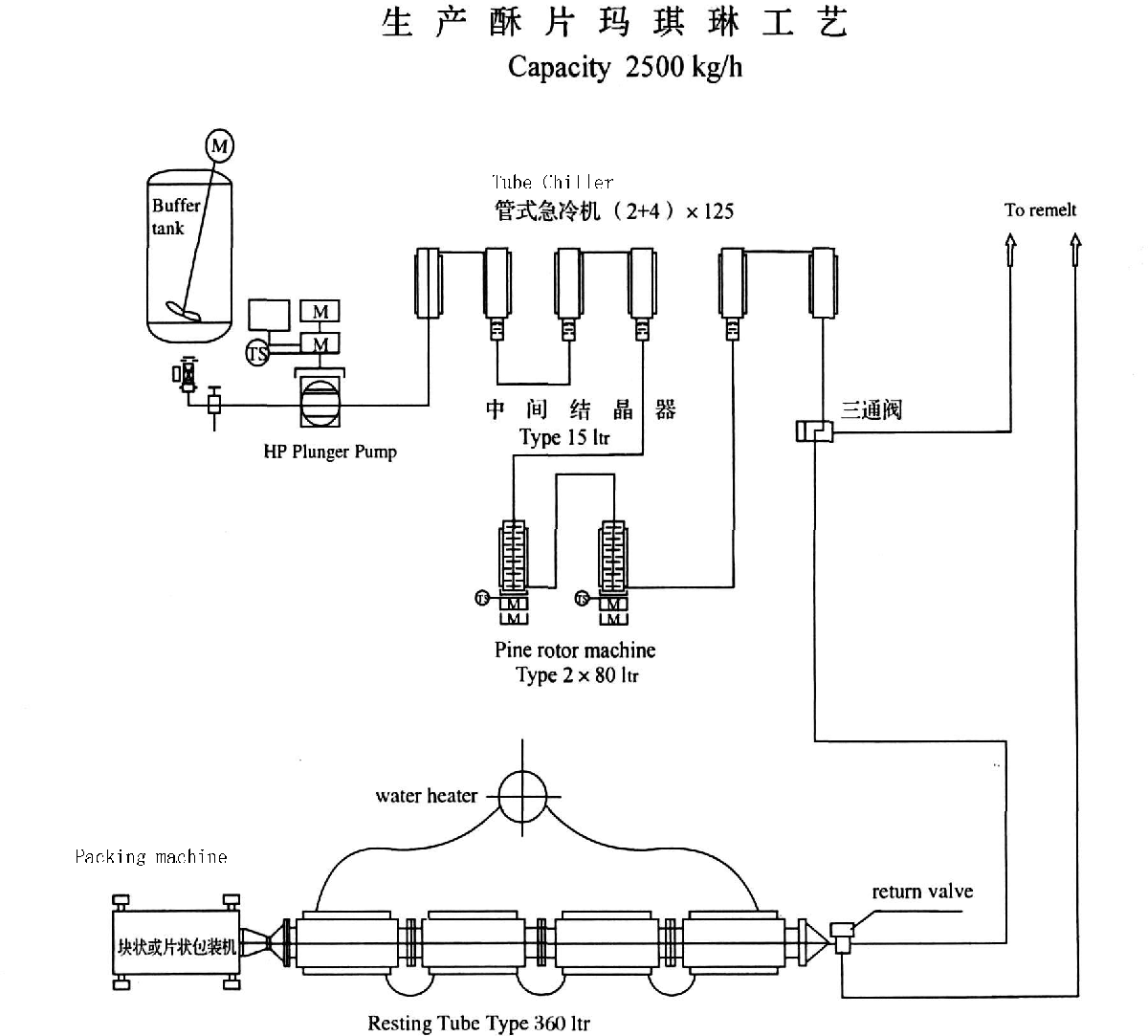

Njira yoyimira kupanga margarine wophwanyika ndi makina oziziritsira chubu ndi iyi:

Pampu yopopera mpweya wopanikizika kwambiri ※ Chosinthira kutentha cha pamwamba chopopera mpweya ...

Ntchito ya crystallizer yapakati ndi yofanana ndi ya stirging kneader. Ili pa chitoliro chozimitsira cha makina okonzera ndipo imayendetsedwa kuti izungulire ndi shaft yodulira ya makina okonzera.

Ndikosavuta kusintha kayendedwe ka ntchito yopangira zinthu kuti apange margarine wophwanyika pogwiritsa ntchito makina oziziritsira chubu. Cholinga chosintha njira yopangira zinthu chingapezeke mwa kusintha njira yolumikizira chitoliro cholumikizira pakati pa gulu la chitoliro choziritsira (gawo A) ndi gawo loziritsira (gawo B), zomwe zimakhala zosavuta kugwiritsa ntchito. Mwachitsanzo, gawo loziritsira (gawo B) likhoza kuyikidwa pakati pa chitoliro choziritsira cha gawo A, kutsata kuyenda kwa A 1 ※A 2 ※B1 ※B2 ※A 3 ※A 4, kapena kusintha kuyenda kwa A 1 ※A 2 ※A 3 ※A 4 ※B1 ※B2. Mwa kungosintha njira yopangira zinthu kungathandize kuti zinthu zikhale bwino. Mu njira yomwe ili pamwambapa, njira yoyika gawo B pakati pa chitoliro choziritsira cha gawo A ndiyoyenera kwambiri popanga mafuta a masamba pogwiritsa ntchito mafuta a kanjedza, omwe atsimikiziridwa nthawi zambiri popanga. Ndipo ngati chinthu chachikulu cha chinthucho ndi ng'ombe, zotsatira zabwino zitha kupezeka poyika gawo B pambuyo pa gawo A.

Mphamvu yokanda imatsimikiziridwa ndi kapangidwe ka chinthucho, mwachitsanzo, mphamvu yayikulu yokanda iyenera kugwiritsidwa ntchito popanga mafuta ndi kupangika pang'onopang'ono kwa kristalo. Mu njira yopangira chitoliro choziziritsa mwachangu, mphamvu yokanda ndi mphamvu ya gulu lapakati ndi mphamvu ya kristalo ndipo chitoliro chokanda (B) chimadzaza ndi mphamvu ya chinthucho, kotero kusintha kwa njira yopangira chinthucho, pakufunika kusintha mphamvu ya njira yokanda, kaya kudzera mu mphamvu ya B unit ikuwonjezeka kapena kuchepa, ikhoza kuwonjezeka kapena kuchepa pakati pa mphamvu ya nkhungu, Izi zitha kuchitika powonjezera ndikuchotsa nthawi yomweyo, kusinthasintha kwambiri.

Mphamvu yokanda imatsimikiziridwa ndi kapangidwe ka chinthucho, mwachitsanzo, mphamvu yayikulu yokanda iyenera kugwiritsidwa ntchito popanga mafuta ndi kupangika pang'onopang'ono kwa kristalo. Mu njira yopangira chitoliro choziziritsa mwachangu, mphamvu yokanda ndi mphamvu ya gulu lapakati ndi mphamvu ya kristalo ndipo chitoliro chokanda (B) chimadzaza ndi mphamvu ya chinthucho, kotero kusintha kwa njira yopangira chinthucho, pakufunika kusintha mphamvu ya njira yokanda, kaya kudzera mu mphamvu ya B unit ikuwonjezeka kapena kuchepa, ikhoza kuwonjezeka kapena kuchepa pakati pa mphamvu ya nkhungu, Izi zitha kuchitika powonjezera ndikuchotsa nthawi yomweyo, kusinthasintha kwambiri.

Nthawi yotumizira: Disembala-30-2021