Margarine Production Technology

CHIDULE CHA AKULUAKULU

Makampani azakudya masiku ano ali ngati mabizinesi ena opanga zinthu osati kungoyang'ana kudalirika komanso mtundu wa zida zopangira chakudya komanso ntchito zosiyanasiyana zomwe wopereka zida zopangira zida amatha kupereka. Kupatula mizere yoyendetsera bwino yomwe timapereka, titha kukhala ogwirizana kuyambira pa lingaliro loyambirira kapena gawo la polojekiti mpaka gawo lomaliza lotumidwa, osaiwala ntchito yofunikira pambuyo pa msika.

Shiputec ali ndi zaka zopitilira 20 pamakampani opanga zakudya komanso ma CD.

MAU OYAMBIRIRA PA TEKNOLOJIA YATHU

MASOMPHENYA NDI KUDZIPEREKA

Gawo la Shiputec limapanga, kupanga ndi kugulitsa njira zopangira uinjiniya ndi zodzipangira okha kumakampani a mkaka, chakudya, zakumwa, zam'madzi, zamankhwala ndi zosamalira anthu kudzera m'makampani ake apadziko lonse lapansi.

Ndife odzipereka kuthandiza makasitomala athu padziko lonse lapansi kuti apititse patsogolo magwiridwe antchito ndi phindu lazopanga zawo ndi njira zawo. Timakwaniritsa izi popereka zinthu zambiri ndi mayankho kuchokera kuzinthu zopangidwira kupanga mapangidwe azinthu zonse zomwe zimathandizidwa ndi ntchito zapamwamba padziko lonse lapansi komanso ukadaulo wachitukuko.

Tikupitiliza kuthandiza makasitomala athu kukhathamiritsa magwiridwe antchito ndi phindu la fakitole yawo munthawi yonse yautumiki wawo ndi chithandizo chogwirizana ndi zosowa zawo payekhapayekha kudzera mumakasitomala olumikizidwa ndi netiweki ya magawo ena.

KHALANI NDI customer

Shiputec imapanga, kupanga ndi kukhazikitsa mizere yamakono, yogwira mtima kwambiri komanso yodalirika yopangira chakudya. Popanga mafuta opangidwa ndi crystallized monga margarine, batala, kufalikira ndi kufupikitsa Shiputec imapereka mayankho omwe amaphatikizanso mizere yazakudya zokongoletsedwa monga mayonesi, sosi ndi mavalidwe.

KUKHALA KWA MARGARINE

Margarine ndi mankhwala okhudzana nawo ali ndi gawo la madzi ndi gawo la mafuta ndipo motero amatha kudziwika ngati ma emulsions amadzi mu mafuta (W / O) momwe gawo la madzi limamwazikana bwino ngati madontho mu gawo lamafuta osalekeza. Malingana ndi kugwiritsidwa ntchito kwa mankhwala, mapangidwe a gawo la mafuta ndi kupanga mapangidwe amasankhidwa moyenerera.

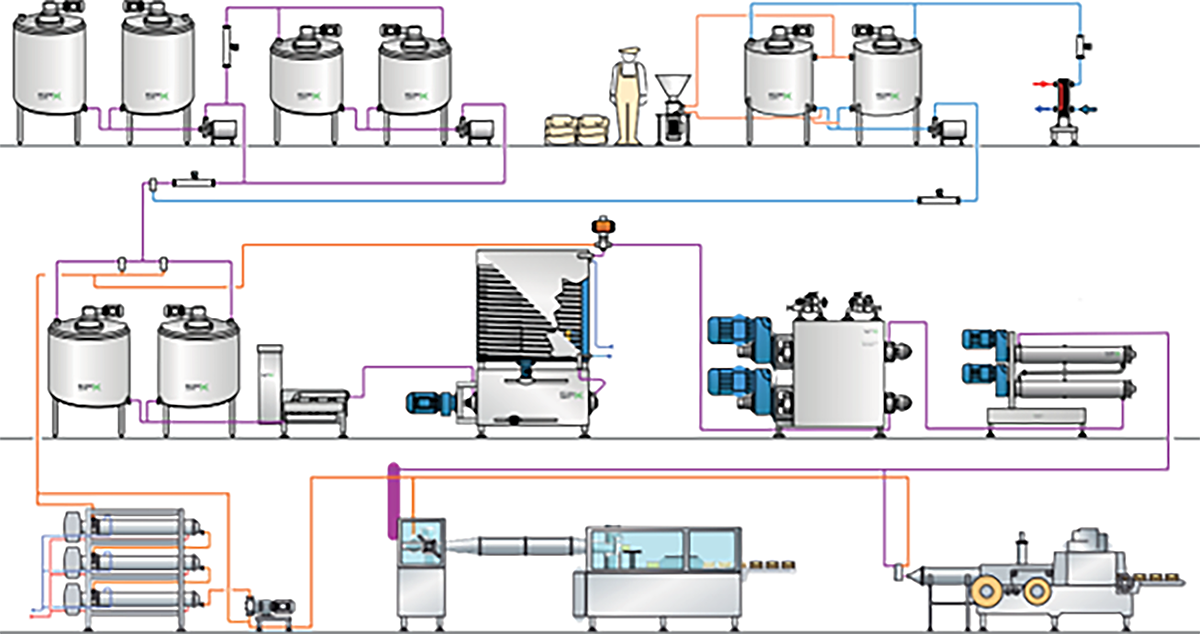

Kupatula zida za crystallization, malo opangira ma margarine amakono ndi zinthu zina zofananira zidzaphatikizanso matanki osiyanasiyana osungira mafuta komanso emulsifier, gawo lamadzi ndi kukonzekera emulsion; kukula ndi kuchuluka kwa akasinja amawerengedwa kutengera mphamvu ya mbewu ndi katundu mbiri. Malowa amaphatikizanso gawo la pasteurization ndi malo osungunula. Chifukwa chake, njira zopangira zitha kugawidwa m'njira zotsatirazi (chonde onani chithunzi 1):

KUKONZEKERA KWA TH E GASE YA MADZI NDI GAWO LA MAFUTA (ZONE 1)

Gawo lamadzi nthawi zambiri limakonzedwa molingana ndi tanki yamadzi. Madzi amayenera kukhala abwino kumwa. Ngati madzi abwino akumwa sangakhale otsimikizika, madziwo amatha kusinthidwa kale pogwiritsa ntchito ma UV kapena makina osefera.

Kupatula madzi, gawo la madzi likhoza kukhala ndi mchere kapena brine, mapuloteni a mkaka (margarine ya tebulo ndi kufalikira kwa mafuta ochepa), shuga (puff pastry), stabilizers (kuchepa ndi kufalikira kwa mafuta ochepa), zotetezera ndi zokometsera zosungunuka madzi.

Zosakaniza zazikulu mu gawo lamafuta, kuphatikiza mafuta, nthawi zambiri zimakhala ndi mafuta osakanikirana ndi mafuta osiyanasiyana. Kuti tikwaniritse margarine ndi mawonekedwe omwe amafunidwa ndi magwiridwe antchito, chiŵerengero cha mafuta ndi mafuta mumafuta ophatikizana ndichofunikira pakuchita komaliza.

Mafuta ndi mafuta osiyanasiyana, monga mafuta ophatikizika kapena mafuta amodzi, amasungidwa m'matangi osungiramo mafuta omwe amayikidwa kunja kwa malo opangira. Izi zimasungidwa pamalo otetezeka osungiramo kutentha pamwamba pa malo osungunuka a mafuta ndi pansi pa chipwirikiti kuti apewe kugawanika kwa mafuta ndi kulola kugwidwa mosavuta.

Kupatula kuphatikizika kwamafuta, gawo lamafuta nthawi zambiri limakhala ndi zinthu zazing'ono zosungunuka mafuta monga emulsifier, lecithin, kukoma, mtundu ndi antioxidants. Zosakaniza zazing'onozi zimasungunuka muzosakaniza zamafuta musanawonjezedwe gawo lamadzi, motero musanayambe ndondomeko ya emulsification.

KUKONZEKERA KWA EMULSION ( ZONE 2 )

Emulsion imakonzedwa ndikusamutsa mafuta osiyanasiyana ndi mafuta kapena mafuta ophatikizika ku thanki ya emulsion. Kawirikawiri, mafuta osungunuka kwambiri kapena osakaniza mafuta amawonjezeredwa poyamba ndikutsatiridwa ndi mafuta otsika osungunuka ndi mafuta amadzimadzi. Kuti amalize kukonzekera gawo lamafuta, emulsifier ndi zinthu zina zazing'ono zosungunuka zamafuta zimawonjezeredwa kusakaniza kwamafuta. Pamene zosakaniza zonse za gawo la mafuta zasakanizidwa bwino, gawo la madzi limawonjezeredwa ndipo emulsion imapangidwa pansi pa kusakanikirana kwakukulu koma kolamulidwa.

Kachitidwe osiyana angagwiritsidwe ntchito metering zosiyanasiyana zosakaniza kwa emulsion amene awiri ntchito batch-wise:

Dongosolo la mita yoyenda

Sitima ya tank yoyezera

A mosalekeza mu mzere emulsification dongosolo ndi zochepa ankakonda koma ntchito njira mwachitsanzo mkulu mphamvu mizere kumene malo ochepa kwa akasinja emulsion zilipo. Dongosolo ili ntchito dosing mapampu ndi misa otaya mamita kulamulira chiŵerengero cha magawo anawonjezera mu thanki yaing'ono emulsion.

Machitidwe omwe tawatchulawa akhoza kulamulidwa kwathunthu. Zomera zina zakale, komabe, zimakhala ndi machitidwe okonzekera emulsion pamanja koma izi ndizovuta ndipo sizikuvomerezedwa kuti zikhazikitsidwe lero chifukwa chotsatira malamulo okhwima.

The otaya mita dongosolo zachokera mtanda wanzeru emulsion kukonzekera imene magawo osiyanasiyana ndi zosakaniza anayeza ndi misa otaya mamita pamene anasamutsidwa zosiyanasiyana gawo akasinja kukonzekera mu thanki emulsion. Kulondola kwadongosolo lino ndi +/-0.3%. Dongosololi limadziwika ndi kusamva kwake kuzinthu zakunja monga kugwedezeka ndi dothi.

Dongosolo la tanki yoyezera lili ngati makina otaya mita yotengera kukonzekera kwa emulsion ya batch-wise. Apa kuchuluka kwa zosakaniza ndi magawo anawonjezera mwachindunji kwa thanki emulsion amene wokwera pa katundu maselo kulamulira ndalama anawonjezera kwa thanki.

Childs, awiri akasinja dongosolo ntchito pokonzekera emulsion kuti athe kuthamanga crystallization mzere mosalekeza. Tanki iliyonse imagwira ntchito ngati tanki yokonzekera ndi kusungirako (thanki ya emulsion), motero mzere wa crystallization udzadyetsedwa kuchokera ku thanki imodzi pamene gulu latsopano lidzakonzedwa mu lina ndi mosemphanitsa. Izi zimatchedwa flip-flop system.

Njira yothetsera pamene emulsion imakonzedwa mu thanki imodzi ndipo ikakonzeka imasamutsidwa ku thanki ya bafa kuchokera kumene mzere wa crystallization umadyetsedwa ndi njira. Dongosololi limatchedwa premix/buffer system.

PASTEURIZATION ( ZONE 3 )

Kuchokera ku bafa thanki ndi emulsion nthawi zonse amapopa kudzera mwina mbale kutentha exchanger (PHE) kapena otsika kuthamanga scraped pamwamba kutentha exchanger (SSHE), kapena kuthamanga SSHE kwa pasteurization isanafike crystallization mzere.

Pazamafuta athunthu, PHE imagwiritsidwa ntchito nthawi zambiri. Kwa matembenuzidwe amafuta ochepa pomwe emulsion ikuyembekezeka kuwonetsa kukhuthala kwakukulu komanso kwa ma emulsion omwe amatha kutentha (monga ma emulsion okhala ndi mapuloteni ambiri) dongosolo la SPX ngati njira yochepetsera kapena SPX-PLUS ngati njira yolimbikitsira kwambiri ikulimbikitsidwa.

Njira ya pasteurization ili ndi zabwino zingapo. Zimalepheretsa kukula kwa bakiteriya ndi kukula kwa tizilombo tating'onoting'ono tating'ono, motero kumapangitsa kukhazikika kwa microbiological kwa emulsion. Pasteurization wa gawo madzi yekha ndi zotheka, koma pasteurization wathunthu emulsion amakonda kuyambira pasteurization ndondomeko ya emulsion adzakhala mini-mise okhalamo nthawi pasteurized mankhwala kudzaza kapena kulongedza katundu chomaliza. Komanso, mankhwala amachitiridwa mu mzere ndondomeko kuchokera pasteurization kudzaza kapena kulongedza katundu chomaliza ndi pasteurization wa zinthu rework aliyense amaonetsetsa pamene wathunthu emulsion ndi pasteurized.

Komanso, pasteurization wa emulsion wathunthu amaonetsetsa kuti emulsion kudyetsedwa kwa mzere crystallization pa kutentha zonse kukwaniritsa magawo processing zonse, kutentha mankhwala ndi kapangidwe mankhwala. Kuonjezera apo, zochitika za emulsion yokonzedweratu yomwe imadyetsedwa ku zida za crystallization imatetezedwa pamene emulsion imayendetsedwa bwino ndikudyetsedwa ku mpope wothamanga kwambiri pa kutentha kwa 5-10 ° C kuposa kusungunuka kwa gawo la mafuta.

A mmene pasteurization ndondomeko pambuyo yokonza emulsion pa 45-55 ° C monga Kutentha ndi atagwira zinayendera emulsion pa 75-85 ° C kwa 16 sec. ndipo kenako kuzizira kwa kutentha kwa 45-55 ° C. Kutentha kotsiriza kumadalira kusungunuka kwa gawo la mafuta: kumtunda kwa malo osungunuka, kutentha kwapamwamba.

KUCHULUKA, KUKWITSA MTIMA NDI KUKANDA (ZONE 4)

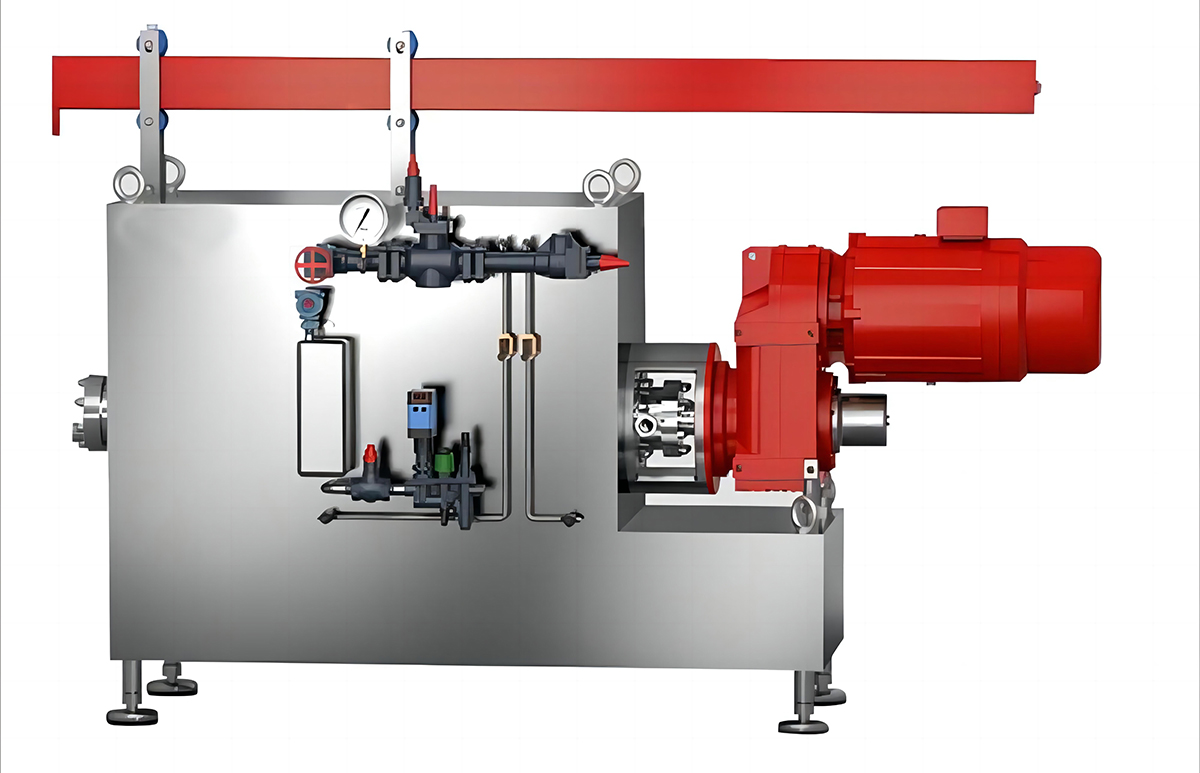

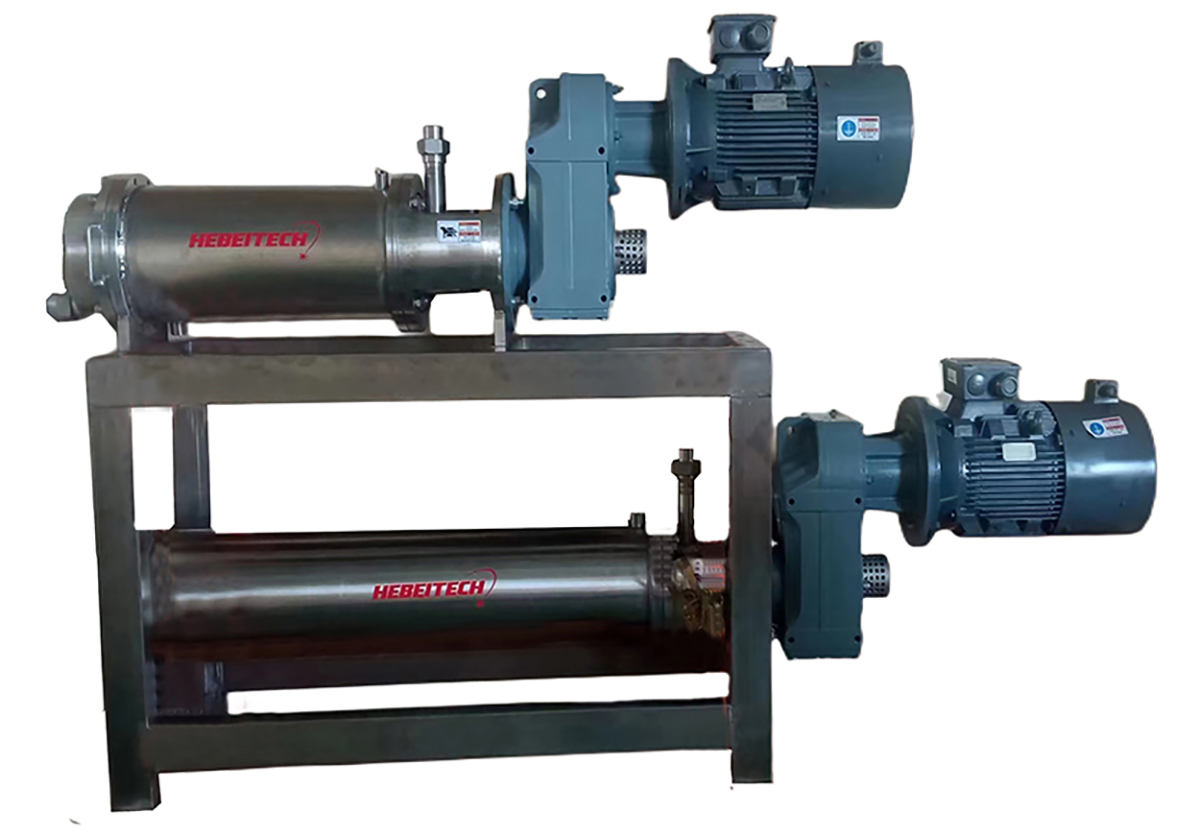

Emulsion imapopedwa ku mzere wa crystallization pogwiritsa ntchito pampu ya pistoni yapamwamba (HPP). Mzere wa crystallization wopangira margarine ndi zinthu zina zogwirizana nazo nthawi zambiri zimakhala ndi SSHE yothamanga kwambiri yomwe imakhazikika ndi ammonia kapena Freon mtundu wa kuziziritsa media. Pin rotor makina (ma) ndi / kapena makristali apakatikati nthawi zambiri amaphatikizidwa pamzerewu kuti awonjezere kulimbikira kowonjezera komanso nthawi yopanga zinthu zapulasitiki. Chubu chopumula ndi sitepe yomaliza ya mzere wa crystallization ndipo imaphatikizidwa pokhapokha ngati mankhwalawa ali odzaza.

Mtima wa mzere wa crystallization ndi kuthamanga kwapamwamba kwa SSHE, komwe emulsion yotentha imakhala yoziziritsa kwambiri komanso yonyezimira pakatikati pa chubu chozizira. The emulsion ndi efficiently scrapers ndi kasinthasintha scrapers, motero emulsion ndi ozizira ndi kneaded imodzi. Pamene mafuta mu emulsion crystallizes, mafuta makhiristo kupanga atatu azithunzithunzi maukonde entrapping m'malovu madzi ndi mafuta amadzimadzi, chifukwa mankhwala ndi katundu pulasitiki theka-olimba chikhalidwe.

Kutengera mtundu wazinthu zomwe zikuyenera kupangidwa komanso mtundu wamafuta omwe amagwiritsidwa ntchito pa chinthucho, kasinthidwe ka mzere wa crystallization (ie dongosolo la machubu oziziritsa ndi makina a pini rotor) akhoza kusinthidwa kuti apereke kasinthidwe koyenera kwa chinthucho.

Popeza mzere wa crystallization nthawi zambiri umapanga mafuta oposa amodzi, SSHE nthawi zambiri imakhala ndi magawo awiri kapena kuposerapo ozizira kapena machubu oziziritsa kuti akwaniritse zofunikira za mzere wosinthika wa crystallization. Popanga mafuta osakanikirana osiyanasiyana ophatikizika osiyanasiyana, kusinthasintha kumafunika chifukwa mawonekedwe a crystallization a ma crystallizations amatha kusiyana ndi kuphatikiza kumodzi.

The ndondomeko crystallization, zinthu processing ndi magawo processing ali ndi chikoka chachikulu pa makhalidwe a margarine yomaliza ndi kufalitsa mankhwala. Popanga mzere wa crystallization, ndikofunika kuzindikira makhalidwe azinthu zomwe zimakonzedwa kuti zipangidwe pamzere. Kuti muteteze ndalama zamtsogolo, kusinthasintha kwa mzerewo komanso magawo omwe amatha kuwongolera payekhapayekha ndikofunikira, chifukwa kuchuluka kwa zinthu zomwe zimakonda kutha kusintha ndi nthawi komanso zopangira.

Kuchuluka kwa mzere kumatsimikiziridwa ndi malo ozizira omwe alipo a SSHE. Makina amitundu yosiyanasiyana amapezeka kuyambira otsika mpaka mizere yayikulu. Komanso magawo osiyanasiyana osinthika amapezeka kuchokera ku zida za chubu imodzi kupita ku mizere ingapo yamachubu, motero mizere yosinthira yosinthika kwambiri.

Pambuyo pozizira mu SSHE, amalowetsa makina a pin rotor ndi / kapena crystallizers apakatikati momwe amaponderezedwa kwa nthawi inayake komanso mwamphamvu kuti athandize kupititsa patsogolo maukonde amitundu itatu, omwe pa mlingo waukulu ndi pulasitiki. Ngati mankhwalawa akuyenera kugawidwa ngati chinthu chokulungidwa, chidzalowanso mu SSHE chisanakhazikike mu chubu chopumula chisanayambe kukulunga. Ngati mankhwalawa adzazidwa mu makapu, palibe chubu chopumula chomwe chimaphatikizidwa mu mzere wa crystallization.

KUTIKA, KUDZAZA NDI KUKONZERA ( ZONE 5 )

Makina osiyanasiyana onyamula ndi kudzaza akupezeka pamsika ndipo sadzafotokozedwa m'nkhaniyi. Komabe, kusinthasintha kwa mankhwalawa kumakhala kosiyana kwambiri ngati kumapangidwa kuti azidzaza kapena kudzazidwa. Ndizodziwikiratu kuti chinthu chopakidwa chimayenera kuwonetsa mawonekedwe olimba kuposa chodzazidwa ndipo ngati mawonekedwewo sali bwino, mankhwalawa amapatutsidwa ku makina osungunula, kusungunuka ndikuwonjezedwa ku tanki ya bafa kuti akonzenso. Machitidwe osiyana otsitsimula alipo koma machitidwe omwe amagwiritsidwa ntchito kwambiri ndi PHE kapena low pressure SSHE.

ZOCHITA

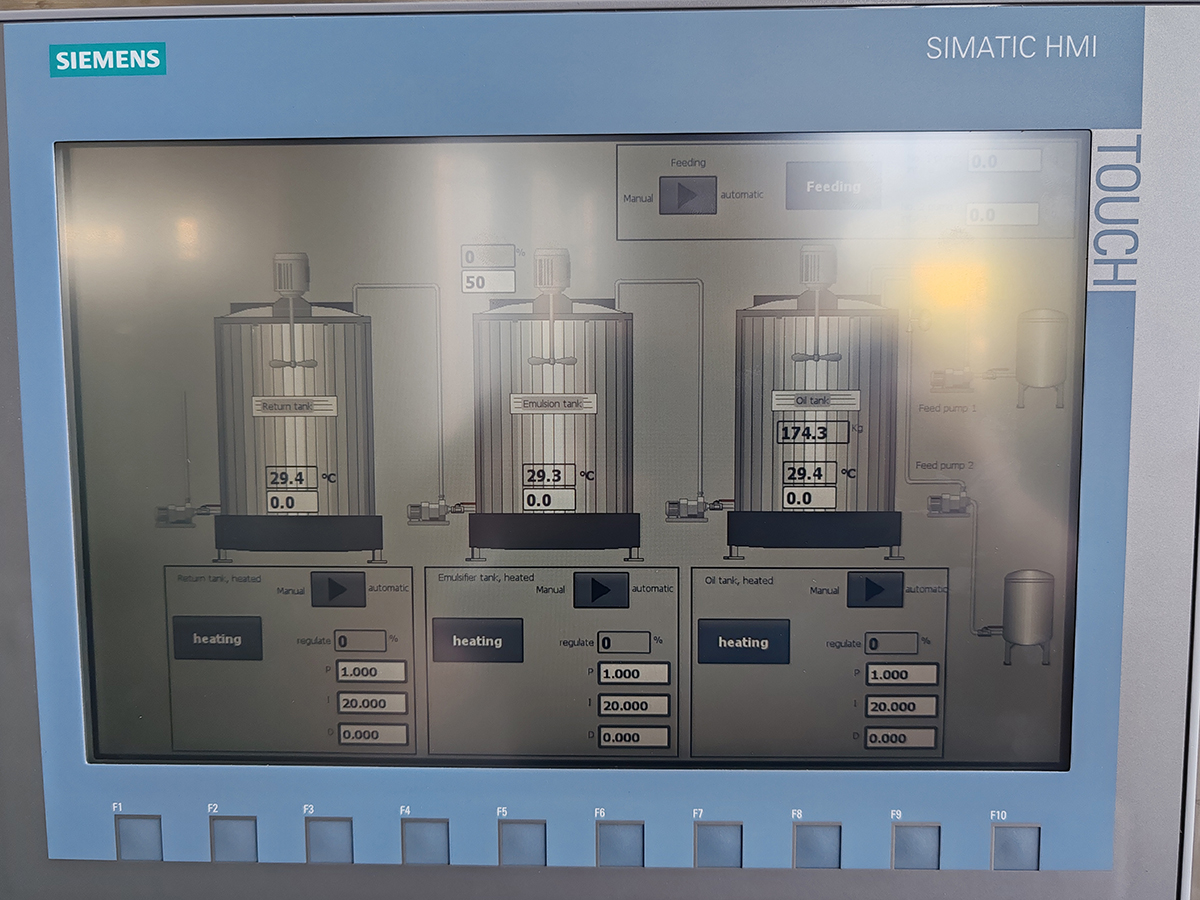

Margarine, monga zakudya zina, ali m'mafakitale ambiri masiku ano amapangidwa motsatira njira zowunikira. Njirazi nthawi zambiri zimaphatikiza zosakaniza, kupanga ndi zomaliza sizimangowonjezera chitetezo cha chakudya komanso kuti chakudya chizikhala chokhazikika. Zofuna za traceability zitha kukhazikitsidwa pamakina owongolera a fakitale ndipo dongosolo lowongolera la Shiputec lidapangidwa kuti liziwongolera, kulemba ndikulemba zofunikira ndi magawo okhudzana ndi kupanga kwathunthu.

Dongosolo lowongolera lili ndi chitetezo cha mawu achinsinsi ndipo limakhala ndi mbiri yakale yodula magawo onse omwe akukhudzidwa ndi mzere wokonza margarine kuchokera ku zambiri zamaphikidwe mpaka kuwunika komaliza kwazinthu. Kudula kwa deta kumaphatikizapo mphamvu ndi kutulutsa mphamvu ya mpope (l / ola ndi kupanikizika kumbuyo), kutentha kwa mankhwala (kuphatikiza ndondomeko ya pasteurization) panthawi ya crystallization, kutentha kozizira (kapena kuzizira kwa media media) kwa SSHE, liwiro la SSHE ndi makina a pin rotor komanso katundu wa motors omwe akuyendetsa pampu yothamanga kwambiri, SSHE ndi makina a pini rotor.

Dongosolo lowongolera

Panthawi yokonza, ma alarm adzatumizidwa kwa wogwiritsa ntchito ngati magawo opangira mankhwalawo ali kunja kwa malire; izi zimayikidwa mu mkonzi wa Chinsinsi asanayambe kupanga. Ma alarm awa akuyenera kuvomerezedwa pamanja ndikuchitapo kanthu motsatira ndondomeko. Ma alarm onse amasungidwa mu alarm system yakale kuti awonedwe mtsogolo. Chogulitsacho chikachoka pamzere wodzaza bwino kapena wodzaza, chimakhala chosiyana ndi dzina lachinthu chomwe chimakhala ndi tsiku, nthawi ndi nambala yozindikiritsa batch kuti muzitsatira. Mbiri yonse ya njira zonse zopangira zomwe zikukhudzidwa pakupanga zinthuzo zimayikidwa kuti zitetezeke kwa wopanga ndi wogwiritsa ntchito, wogula.

CIP

Malo oyeretsera CIP (CIP = kuyeretsa m'malo) ndi gawo la malo amakono a margarine popeza malo opangira margarine ayenera kutsukidwa nthawi zonse. Pazinthu zachikhalidwe za margarine kamodzi pa sabata ndi nthawi yoyeretsa. Komabe, pazamankhwala okhudzidwa kwambiri monga mafuta otsika (ochuluka m'madzi) ndi/kapena mapuloteni ochuluka okhala ndi zinthu, tizikhala ndi nthawi zazifupi pakati pa CIP.

M'malo mwake, machitidwe awiri a CIP amagwiritsidwa ntchito: Zomera za CIP zomwe zimagwiritsa ntchito zoyeretsera kamodzi kokha kapena zomera zovomerezeka za CIP zomwe zimagwira ntchito pogwiritsa ntchito njira yosungiramo zinthu zoyeretsera kumene mauthenga monga lye, asidi ndi / kapena mankhwala ophera tizilombo amabwezeretsedwa ku matanki osungiramo CIP atatha kugwiritsidwa ntchito. Njira yotsirizirayi ndiyomwe imakonda chifukwa imayimira njira yothanirana ndi chilengedwe komanso ndiyothandiza pazachuma pakugwiritsa ntchito zoyeretsera ndipo motero mtengo wake.

Ngati mizere ingapo yopangira iyikidwa mufakitale imodzi, ndizotheka kukhazikitsa njira zoyeretsera zofananira kapena makina a satana a CIP. Izi zimapangitsa kuchepetsa kwambiri nthawi yoyeretsa komanso kugwiritsa ntchito mphamvu. Magawo a ndondomeko ya CIP amayendetsedwa okha ndikulowetsedwa kuti atsatire pambuyo pake mudongosolo lowongolera.

MAWU OTSIRIZA

Popanga margarine ndi mankhwala okhudzana nawo, ndikofunika kukumbukira kuti sizongowonjezera zinthu monga mafuta ndi mafuta ogwiritsidwa ntchito kapena maphikidwe a mankhwala omwe amatsimikizira ubwino wa mankhwala omaliza komanso makonzedwe a chomera, magawo opangira zinthu komanso momwe zomera zimakhalira. Ngati mzere kapena zida sizikusungidwa bwino, pali chiopsezo kuti mzerewo sukuyenda bwino. Chifukwa chake, kuti apange zinthu zabwino kwambiri, chomera chogwira ntchito bwino ndichofunika koma kusankha mafuta osakanikirana ndi mikhalidwe yomwe imagwirizana ndi kugwiritsa ntchito komaliza kwa chinthucho ndikofunikiranso komanso kusanja koyenera ndikusankha magawo azomera. Pomaliza mankhwala omaliza ayenera kutenthedwa molingana ndi kugwiritsidwa ntchito komaliza.

Nthawi yotumiza: Dec-19-2023