Mzere Wopanga Msuzi wa Custard

Mzere Wopanga Msuzi wa Custard

Mzere Wopanga Msuzi wa Custard

Kanema Wopanga:https://www.youtube.com/watch?v=AkAcycJx0pI

Amzere wopanga msuzi wa custardZimaphatikizapo njira zingapo zodzipangira zokha komanso zodzipangira zokha kuti apange msuzi wa custard bwino, mosasinthasintha, komanso mwaukhondo. Pansipa pali kufotokozedwa mwatsatanetsatane kwa magawo wamba omwe amapezeka mu mzere wopanga msuzi wa custard:

1. Kusamalira ndi Kukonzekera Zosakaniza

- Kulandira ndi Kusunga Mkaka

- Mkaka wosaphika umalandiridwa, kuyesedwa ngati uli wabwino, ndikusungidwa m'malo osungiramo zinthu zoziziritsa kukhosi.

- Njira ina: Ufa wa mkaka wokonzedwanso + madzi (kuti ukhale nthawi yayitali).

- Kusamalira Shuga ndi Zotsekemera

- Shuga, madzi a chimanga, kapena zotsekemera zina zimayesedwa ndi kusungunuka.

- Kukonza Ufa wa Dzira ndi Dzira

- Mazira amadzimadzi (osaphikidwa) kapena ufa wa dzira amasakanizidwa ndi madzi.

- Wowuma ndi Zokhazikika

- Utachi wa chimanga, wosinthidwa starch, kapena zokhuthala (monga carrageenan) zimasakanizidwa kale kuti zisapangike.

- Zokometsera ndi Zowonjezera

- Vanila, caramel, kapena zokometsera zina, pamodzi ndi zotetezera (ngati pakufunika), zimakonzedwa.

2. Kusakaniza ndi Kusakaniza

- Kusakaniza Konse Kapena Kosalekeza

- Zosakaniza zimasakanizidwa muchosakanizira chodula kwambirikapenathanki yosakanikirana kalekutentha koyenera (kuti mupewe kukhuthala msanga).

- Homogenization ingagwiritsidwe ntchito kuti ikhale yosalala.

3. Kuphika ndi Kusakaniza

- Kuphika Kosalekeza (Chosinthira Kutentha Chokwezedwa Pamwamba)

- Chosakanizacho chimatenthedwa kuti75–85°C (167–185°F)kuyambitsa gelatinization ya wowuma ndikulimbitsa msuzi.

- Kukonza (HTST kapena Batch)

- Nthawi Yochepa Yotentha Kwambiri (HTST) pa72°C (161°F) kwa masekondi 15-20kapena kusakaniza ndi batch pasteurization kuti zitsimikizire kuti tizilombo toyambitsa matenda ndi otetezeka.

- Gawo Loziziritsa

- Kuziziritsa mwachangu ku4–10°C (39–50°F)kusiya kuphika kwina ndikusunga kapangidwe kake.

4. Homogenization (Mwachisawawa)

- Homogenizer Yopanikizika Kwambiri

- Amagwiritsidwa ntchito popanga mawonekedwe osalala kwambiri (amaletsa kukhuthala kwa tinthu tating'onoting'ono).

5. Kudzaza ndi Kulongedza

- Makina Odzaza Okha

- Kudzaza thumba(kwa ogulitsa) kapenakudzaza kwakukulu(kwa utumiki wa chakudya).

- Kudzaza kwa Aseptic(kuti ikhale nthawi yayitali) kapenakudzaza ndi madzi otentha(yosungira zinthu zozungulira).

- Mapangidwe a Maphukusi:

- Mabotolo apulasitiki, makatoni, matumba, kapena zitini.

- Kutsuka kwa nayitrogeni kungagwiritsidwe ntchito kuti kukhale nthawi yayitali.

6. Kuziziritsa ndi Kusunga

- Kuzizira kwa Mphuno (ngati pakufunika)

- Pa custard yosungidwa mufiriji, kuziziritsa mwachangu4°C (39°F).

- Kusungirako Kozizira

- Yosungidwa pa4°C (39°F)kwa custard yatsopano kapena malo ozungulira zinthu zothiridwa ndi UHT.

7. Kuwongolera Ubwino ndi Kuyesa

- Macheke a Kukhuthala(pogwiritsa ntchito ma viscometer).

- Kuwunika pH(cholinga: ~6.0–6.5).

- Kuyesa kwa Tizilombo Tosaoneka ndi Maso(kuchuluka kwa mbale zonse, yisiti/nkhungu).

- Kuwunika kwa Maganizo(kukoma, kapangidwe, mtundu).

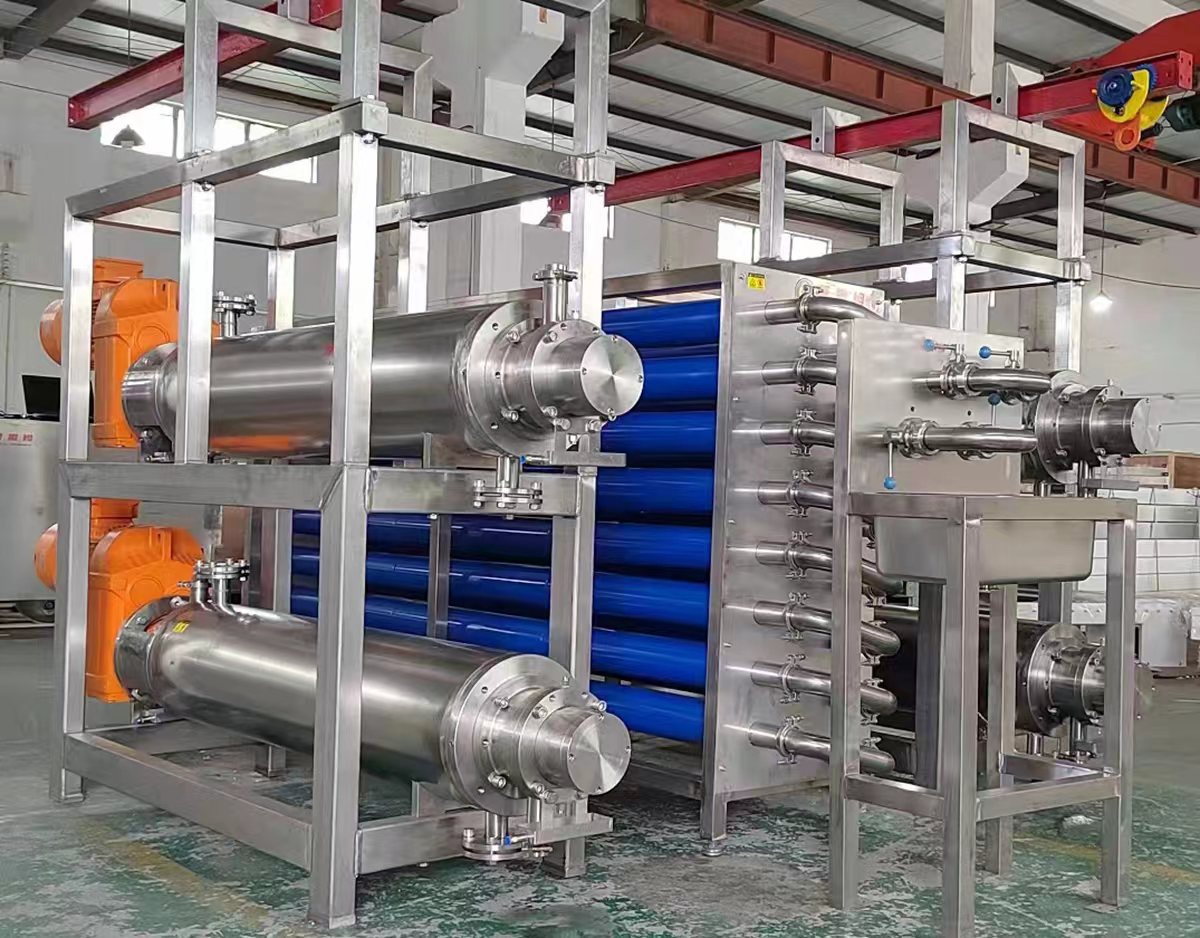

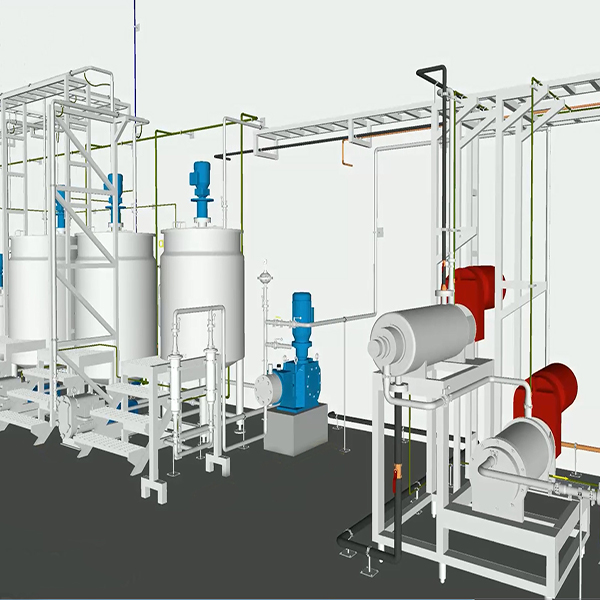

Zipangizo Zofunika Kwambiri mu Mzere Wopangira Msuzi wa Custard

- Matanki Osungira Zinthu(za mkaka, zosakaniza zamadzimadzi).

- Machitidwe Oyezera ndi Kuyeza Mlingo.

- Zosakaniza Zodula Kwambiri ndi Matanki Osakaniza Kwambiri.

- Chotsukira (HTST kapena Batch).

- Chosinthira kutentha pamwamba (chophikira).

- Homogenizer (ngati mukufuna).

- Makina Odzaza (piston, volumetric, kapena aseptic).

- Ma ngalande Oziziritsira.

- Makina Opakira Zinthu (kusindikiza, kulemba zilembo).

Mitundu ya Msuzi wa Custard Yopangidwa

- Custard Yozizira(nthawi yochepa yosungiramo zinthu, kukoma kwatsopano).

- UHT Custard(nthawi yayitali yosungiramo zinthu, yoyeretsedwa).

- Kusakaniza kwa Custard Yophikidwa ndi Ufa(pokonzanso).

Kudziyendetsa ndi Kuchita Bwino

- Machitidwe Olamulira a PLCkuti kutentha ndi kusakaniza kukhale kolondola komanso koyenera.

- Machitidwe a CIP (Oyera-m'malo)za ukhondo.

Kukhazikitsa Malo

Lembani uthenga wanu apa ndipo mutitumizireni